Technologies

W-tube Mixing Method

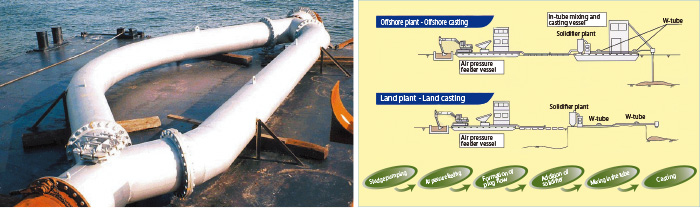

In-tube mixing and solidifying technology

A large quantity of dredged sludge generated by construction in ports and harbors has given rise to a big problem of securing places for its disposal. Meanwhile, attempts are being made to recycle dredged sludge into useful materials.

The W-Tube Mixing Method is a method which enables recycling of the sludge. In this method, soft sludge with high water content is made into a high-quality material with sufficient strength with addition of solidifiers.

Features

Thorough stirring

Mixing in plug flows and collision between plug flows and the pipe wall and among the plug flows in the process of diversion and conversion of flows in the W-tubes facilitates stirring and kneading of materials.

Simple structure

W-tubes, with their simple structure and low resistance, can reduce energy loss. Impurities can be easily removed from the removal hatches.

It enables kneading at short distance

The use of the W-tubes enables kneading at a short distance. Therefore, this method has little risk of blockage and has an advantage in long-distance pressure feeding.

Economically advantageous

As the W-Tube Mixing Method does not require kneading mixers, a large quantity of dredged sledge can be solidified at low cost and adaptation to upsizing of pressure feeders can be easily achieved.